SHS Steel Application: Top Uses and 12 Smart Ways to Apply It Effectively

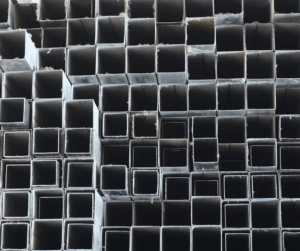

SHS steel, or Square Hollow Section steel, is one of the most versatile materials in modern construction and manufacturing. But beyond its clean lines and high strength, what really makes it valuable is the wide range of SHS steel applications across industries. From large commercial buildings to everyday residential fencing, this material proves its worth through durability, efficiency, and aesthetic appeal.

In this article, we explore the major areas where SHS steel is used, why it performs so well, and what makes it the smart choice for builders and designers alike.

What Makes SHS Steel So Widely Applicable?

Before diving into specific use cases, it’s important to understand why SHS steel application is so broad.

Square Hollow Sections combine strength with form. Their symmetrical shape allows for even load distribution and simple joining, while their hollow structure makes them lighter than solid sections of the same dimensions. This balance of strength, weight, and ease of fabrication opens up a world of possibilities across structural, architectural, and mechanical applications.

SHS Steel Application in Structural Construction

When it comes to load-bearing construction, one of the most essential and widespread SHS steel applications is in structural frameworks. Square hollow sections are known for their ability to handle pressure and weight from multiple directions, making them an ideal choice for critical structural elements in buildings of all types and sizes.

1. Columns and Beams

The clean, square profile of SHS makes it ideal for vertical supports and load-bearing frames. Unlike I-beams or channels, these sections offer balanced strength in all directions, helping reduce twisting and distortion under stress.

2. Framing Systems

For prefabricated buildings and modular homes, SHS sections are used to construct skeleton frames. Their lightweight nature allows for fast and easy assembly without compromising on stability.

3. Roof Structures and Trusses

SHS steel provides an efficient solution for roofing systems, especially in warehouses and industrial facilities. It combines strength and ease of installation, making large-span coverage more feasible.

Architectural SHS Steel Applications

In modern architecture, SHS profiles are often selected not just for strength, but for their aesthetic value. Their clean edges and symmetrical design add to a structure’s visual appeal.

4. Exposed Structural Elements

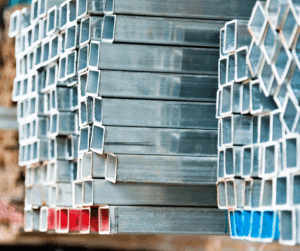

In open-plan or minimalist designs, builders often leave SHS sections visible. Painted, powder-coated, or galvanized SHS steel serves as both structure and statement.

5. Balustrades, Handrails, and Guardrails

Their sleek look and dimensional consistency make square hollow sections perfect for fabricating architectural details like handrails or balcony frames.

6. Canopies and Awnings

When used in roofing extensions or shade structures, SHS provides durability and a modern, tidy appearance, all while withstanding wind and weather loads.

Residential SHS Steel Applications

Another advantage of using square hollow sections in structural work is their compatibility with other materials. Whether combined with concrete slabs or timber paneling, SHS steel creates a versatile skeleton that supports diverse architectural styles and construction methods. It’s also easier to weld and bolt compared to asymmetrical profiles, which helps speed up on-site assembly and reduces labor costs.

The everyday home is another space where SHS steel application is more common than you might think.

7. Fencing and Gates

Square hollow sections offer a clean, uniform look that suits modern homes. They’re strong enough to provide security, and light enough for easy handling and installation.

8. Carports and Pergolas

Builders often choose SHS profiles for carport frames and pergola posts. They offer clean lines and are easy to coat or paint to match a home’s exterior.

9. Furniture Frames and Custom Fixtures

In some cases, SHS sections are used in custom furniture design, particularly for outdoor tables, benches, or industrial-style interior pieces.

Industrial and Infrastructure Applications

On a larger scale, SHS steel application is critical in industrial buildings and civil infrastructure.

10. Factories and Warehouses

Whether it’s a storage racking system or a full warehouse frame, SHS is often the backbone of industrial space. Its easy connection points and capacity to bear large vertical and lateral loads make it a top pick.

11. Bridges and Walkways

In smaller pedestrian bridges or platforms, SHS sections are used for both decking and railing systems due to their strength and weather resistance.

12. Machinery Frames and Structural Supports

In industrial environments, SHS is often used to build the structural base of heavy machinery, assembly lines, and support racks.

SHS Steel Application in Agriculture

Rural and agricultural industries also rely on SHS steel for:

- Shed construction

- Livestock enclosures

- Irrigation system frames

- Farm gates and fencing

Its durability and low maintenance make it well-suited for harsh outdoor conditions and rough use.

SHS Steel in Transport and Logistics

Though not as obvious, SHS sections are also used in the transport industry:

- Vehicle Trailers: Their lightweight and strong nature helps keep trailer frames durable without adding excessive weight.

- Shipping Container Frames: SHS profiles are used in some modular container framing systems.

- Storage Racks and Loading Platforms: Warehouses and docks often use SHS in platform and racking designs.

Specialty and Custom Fabrication Uses

Beyond typical building projects, many metal fabricators work with SHS steel for:

- Art installations and sculptures

- Custom signage frameworks

- Display racks in retail stores

- Steel framing for exhibitions and trade booths

This is a testament to the material’s flexibility. With the right finish and size, SHS can be molded to fit nearly any structural or visual purpose.

Choosing the Right SHS Steel for Your Application

To ensure performance and compliance, it’s critical to match your chosen SHS steel to its intended use:

- For structural loads: Choose thicker walls and check load ratings.

- For outdoor use: Galvanised or powder-coated finishes prevent corrosion.

- For aesthetic purposes: Go for a clean, smooth surface and consistent dimensions.

- For welding and cutting: Mild steel SHS is easier to work with than harder alloys.

Make sure your supplier meets the AS/NZS 1163 standard (in Australia) for structural steel, and always verify product specifications.

Final Thoughts on SHS Steel Application

From skyscrapers to backyard pergolas, SHS steel applications span nearly every sector of construction, manufacturing, and design. Its combination of strength, flexibility, and clean appearance makes it one of the most practical and reliable materials available today.

Whether you’re a homeowner, architect, builder, or engineer, understanding how and where square hollow sections can be used helps ensure your next project is stronger, faster, and more efficient.

Looking for SHS steel tailored to your application?

We supply high-quality, AS-compliant SHS steel in various sizes and finishes. Contact us today for expert advice, cutting services, and fast delivery!

Have questions? We’re here to help! Send us your drawings or specifications for a free, no-obligation quote anytime.

You can find us at our Fanpage Lintel Steel.