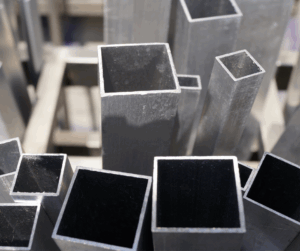

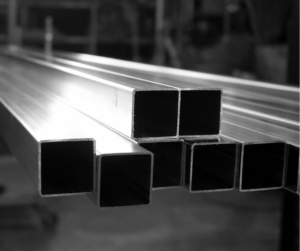

SHS Steel Dimensions: A Complete Guide to Sizes

When choosing structural steel, one of the most important factors to consider is size. For square hollow sections (SHS), dimensions determine everything—from strength and load-bearing capacity to how easily the steel can be installed or connected. In this article, we break down the most common SHS steel dimensions, how they’re measured, and how to choose the right size for your project.

What Are SHS Steel Dimensions?

SHS steel dimensions refer to the measurable attributes of square hollow section steel, including:

- Outside width (W)

- Wall thickness (T)

- Length (L)

These dimensions vary depending on the application. Some SHS sections are small enough for furniture frames; others are large enough to support multi-storey buildings.

Standard SHS Steel Dimensions

SHS steel is manufactured in a wide range of standard sizes to suit different structural and architectural needs. While exact availability may vary by country and supplier, common sizes in millimeters include:

| Outside Width (mm) | Wall Thickness (mm) | Common Uses |

| 25 x 25 | 1.6 – 2.5 | Fencing, furniture, light frames |

| 50 x 50 | 2.0 – 3.0 | Gates, posts, small structures |

| 75 x 75 | 2.5 – 4.0 | Residential frames, support beams |

| 100 x 100 | 3.0 – 5.0 | Commercial structures, columns |

| 150 x 150 | 4.0 – 6.0 | Industrial beams, large load supports |

| 200 x 200 | 6.0 – 10.0 | Heavy-duty columns, warehouse frameworks |

| 250 x 250 | 6.0 – 16.0 | Infrastructure, high-load structures |

Note: Dimensions are for cold-formed SHS steel manufactured to AS/NZS 1163 (in Australia) or similar international standards.

Other important dimensions to consider when selecting a steel tube include the following:

40 x 40 shs

30 x 30 shs

60 x 60 shs

65×65 shs

75 x 75 shs

80 x 80 shs

89 x 89 x 5 shs

90×90 shs

125×125 shs

180×180 shs

89×89 shs

How SHS Steel Dimensions Are Measured

To ensure precision in fabrication and load calculations, SHS steel dimensions are defined using three key metrics:

1. Outside Width

The total outer measurement across one side of the square. For example, a 100mm x 100mm SHS has 100mm on each side.

2. Wall Thickness

The distance between the inner and outer walls of the steel section. Thicker walls mean more strength but also more weight.

3. Length

Standard lengths are typically 6,000mm (6m) or 8,000mm (8m). However, custom cutting services allow for precise lengths to suit individual projects.

All dimensions are usually expressed in millimeters for consistency and clarity in architectural and engineering plans.

Tolerance and Accuracy in SHS Steel Dimensions

In structural applications, dimensional accuracy is critical. That’s why most reputable steel manufacturers ensure:

- Tight tolerance on width and thickness (often ±1–2%)

- Even wall thickness across all sides

- Straightness and squareness of the profile

- Smooth and consistent weld seams

Meeting these tolerances ensures SHS steel dimensions can be reliably used in load calculations and comply with safety standards.

Choosing the Right SHS Steel Dimensions for Your Project

The right dimensions depend on several factors:

1. Load Requirements

- Heavier loads require larger widths and thicker walls.

- For example, a 200 x 200 x 9mm SHS can support significantly more weight than a 50 x 50 x 2mm SHS.

2. Span and Length

Longer spans between supports demand stronger sections. Always calculate bending and deflection before selecting a size.

3. Aesthetic Preferences

In architectural applications, a slim SHS section may be chosen for a clean visual finish, even if not required structurally.

4. Installation and Handling

Larger or thicker SHS sections are heavier and may need cranes or extra labor for installation. Factor this into your planning.

5. Budget

Material cost rises with size and thickness. Efficient use of smaller sections can save costs without sacrificing safety.

Custom vs. Standard SHS Steel Dimensions

While standard sizes cover most needs, many steel suppliers offer custom fabrication:

- Cut-to-length

- Precision mitre cuts for joints

- Special wall thicknesses for engineered loads

- Additional processing like drilling or notching

This flexibility allows engineers and fabricators to design more efficiently while reducing on-site waste.

SHS Steel Dimensions in Metric and Imperial

Most regions, including Australia, Europe, and Asia, use metric units (millimeters). However, in the U.S. and some parts of the Middle East, imperial units like inches are still in use. For example:

- 2” x 2” SHS = ~50mm x 50mm

- 4” x 4” SHS = ~100mm x 100mm

Always confirm units when ordering steel internationally to avoid mismatches.

SHS Steel Dimension Charts and Tables

Many suppliers provide downloadable SHS dimension tables or online calculators. These tools include data such as:

- Cross-sectional area

- Mass per meter

- Moment of inertia

- Section modulus

This data is crucial for engineers doing structural calculations or designers estimating project weight and cost.

If you need help interpreting these figures, your supplier or structural engineer can guide you.

Final Thoughts on SHS Steel Dimensions

Understanding SHS steel dimensions is essential to selecting the right material for your project—whether you’re building a simple garden frame or a large industrial warehouse.

With a wide range of standard sizes and the option for custom cuts and wall thicknesses, SHS sections offer unmatched flexibility and strength. Always work with a supplier that guarantees tight tolerances, meets national standards, and offers technical support to help you choose the most efficient section for your build.

Need help choosing the right SHS steel dimensions?

Send us your project specs or drawings, and we’ll provide a fast, free quote—plus expert advice to ensure your steel fits perfectly.

You can find us at our Fanpage Lintel Steel.